Challenges of Reliability

Too many product development company, including the global world-class companies, how to improve the reliability of product and reduce warranty cost is always a challenge. For many companies, it is not possible that the product has no failures but many times, those failures are not acceptable for customer, even it is a small failure, which will affect the competition and customer satisfaction in the market.

Moreover, with more and more new technologies and rapid changing customer requirements, many companies have to develop new product to meet future market and customer needs. Those new product and technologies (so called New-Content) will always bring reliability risk in the new market. How to reduce those reliability risks are always challenging as well.

Reliability is a sophisticated and systematic problem, a systematic process and technologies are needed to make sure it is in control. In past 30 years, ITI has been working with global companies in many industries including automotive, aerospace, heavy industry, eletronics and so on to help them establish a system called RPM process, which will help customer plan, proactively prevent and grow reliability before product goes into production. Also RPM9.0 software is developed to realize the process with decades of reliability experience built in.

Traditional Reliability Process

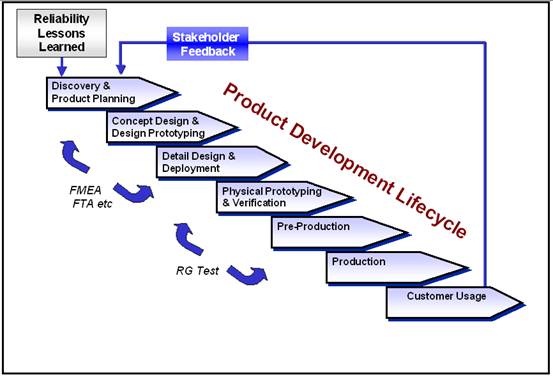

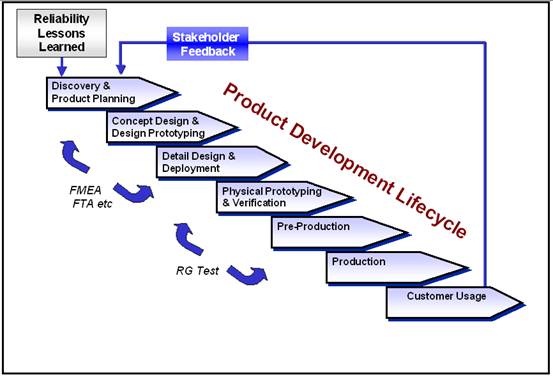

The picture shows below is the traditional reliability process.

Many companies are using typical reliability technologies such as FMEA, FTA and do some RG test in product validation phase. After the product is put in market, some companies will improve the reliability based on warranty data analysis. The major focus of traditional process is fix the problem once the problems occur and try to avoid the problems in new generation product. But

The major shortfalls of traditional reliability process are:

- No systematic process for reliability growth

- RG Planning for all changes not done

- Limited proactive RG Engineering done at system level

- Test results applied as “best fit” for RG - too late in process

- Outcome: RG goals, costs and/or schedule often not met

ITI Reliability Process

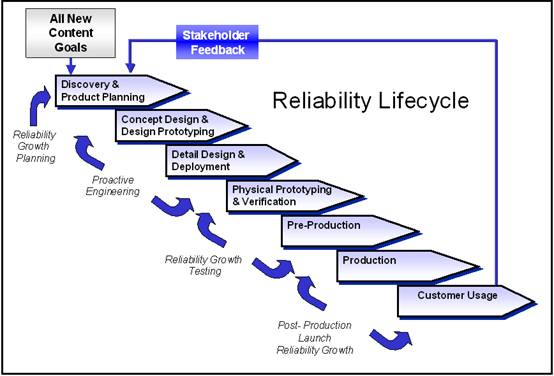

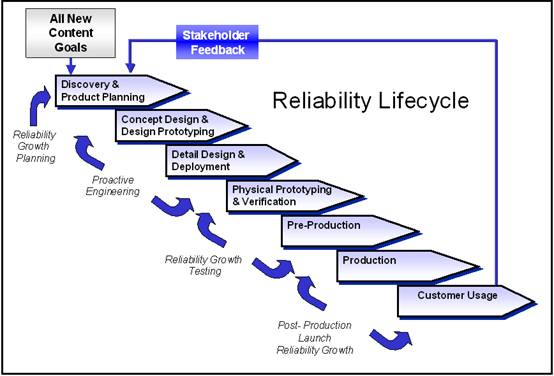

Below is the overall description of ITI reliability process, which is called RPM process.

ITI divides RPM process to 4 major parts including RG planning, proactive engineering, reliability growth test validation and post product lunch RG. This process covers the whole product life cycle from product planning to service.

1. RG planning

RG planning is supposed to do in parallel with product planning to define reliability targets for new product or product upgrade and then to meet the targets, what proactive actions needs to be done and what kind RG test should be conducted. The major steps are as below.

2. Proactive Engineering

Proactive engineering is in the development phase, to apply effective proactive methods such as system engineering (SEALD), reliability technologies (FMEA, FTA, C&E, HALT etc.) to reduce the risk of failures before the prototype is built. Typical proactive technologies include:

- DFX (X could be manufacturing, assembly, cost, six sigma etc)

- Analysis leads design (structure and fatigue, dynamic, CFD, NVH etc.)

- FTA analysis

- FMEA

- C&E analysis

- CLCA (Close loop corrective actions)

- Monte Carlo Analysis

- Risk analysis

The detail process is shown below.

3. RG Test

RG test is the systematic process in product level or system level to make sure the reliability problems are exposed before the product is lunched. The overall steps are:

Once the problems occurs, it has to be analyzed and corrected in new proto to make sure those problems are eliminated. If not, a risk mitigation plan should be supplemented so that the reliability problems can be controlled after the product is released.

Typically RG test is phased and the problems in the former phases should be corrected in next phase. But for small volume product, ITI has customized process to make sure the reliability is achieved as well.

The test planning should be scheduled reasonable based on how many prototypes will be built, how long the development time is permitted. Also the test needs to be tracked strictly to make sure the reliability targets can be met.

What we offer

We will work with customer side by side to help customer establish the RG process, at the same time, transfer the knowhow to customer to really help customer to be successful. During the project, what we offer are as below:

- Underlying technologies training on reliability

- Step by step on job training and implementation of ITI RG process

- Provide RPM software training and real usage of RPM with customer real data

- Provide Consulting on proactive actions such as FMEA, HALT etc and System engineer (SEALD projects) etc.

Benefits to Customers

Implemented correctly a Reliability Growth initiative will produce one or more of the following results:

- Improved Product & Process Quality & Reliability

- Improved Customer Satisfaction & Loyalty

- Increased Market Share & Profitability

- Reduced Product Development Cost & Risk

- Reduced Warranty Claims & Costs

- Transfer the RG process and RG fundamentals to customer

- Train customer the use of RPM software to realize the process